Stabilizer bars are often utilized as a tool for stabilizing the down-hole pump pull rod or tube, keeping it centralized so it does not buckle or flex on the down-stroke, extending pump life and reducing plunger and barrel wear. Stabilizer bars are also used between sinker bars to add centralization to the heavy K-bars, keeping the rods centralized and preventing tubing wear.

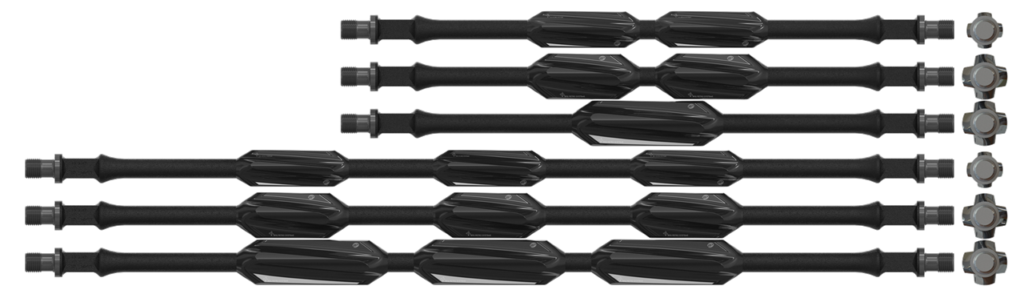

RFG Petro Systems has incorporated a partnership with a domestic forging group to build custom API compliant rods to our specification. Our DS grade rods are made from 4320M, Normalized and Tempered SBQ Steel. 4320M is the preferred grade for D-Special rods, as it features nearly 2% Nickel for increased corrosion resistance in today’s aggressive environments. All RFG products feature Cold-Rolled Formed Threads. Stabilizer Bars are provided with MP Polymer Technology sucker rod guides.

The stabilizer bar rod body diameter is 1″ for both 2-3/8″ or 2-7/8″ tubing applications. This allows for greater rigidity:

- 1.7x more stiff than 7/8″ rod

- 3.16x more stiff than 3/4″ rod.

This larger 1″ rod diameter provides the geometric stiffness and stability which is demanded of the product in the well, proving itself better suited than inferior 7/8″ diameter stabilizer bars on the market.

A 1″ diameter stabilizer bar can be used in 2-3/8″ tubing without issue, as the stabilizer bar has an API 7/8″ forging upset, the 3/4″ & 7/8″ wrench square, and the API specified roll-formed thread pin end with matching pin shoulder. Pin shoulders match 3/4″ or 7/8″ slim hole couplings, preventing a geometric protrusion of the coupling wearing into tubing. The maximum OD of the steel rod is 1.500″ (3/4″ Pin) or 1.625″ (7/8″ Pin), providing ample clearance for 2″ wells (~1.900″ tubing I.D.)

Variants offered:

- 1″ Bar, 3/4″ Pin, 30″ Long, 2 Standard 2.0″ RFG MP Polymer Guides

- 1″ Bar, 3/4″ Pin, 30″ Long, 2 Standard 2.5″ RFG MP Polymer Guides

- 1″ Bar, 3/4″ Pin, 30″ Long, 1 Long 2.5″ RFG MP Polymer Guide

- 1″ Bar, 7/8″ Pin, 30″ Long, 2 Standard 2.0″ RFG MP Polymer Guides

- 1″ Bar, 7/8″ Pin, 30″ Long, 2 Standard 2.5″ RFG MP Polymer Guides

- 1″ Bar, 7/8″ Pin, 30″ Long, 1 Long 2.5″ RFG MP Polymer Guide

- 1″ Bar, 3/4″ Pin, 48″ Long, 3 Standard 2.0″ RFG MP Polymer Guides

- 1″ Bar, 3/4″ Pin, 48″ Long, 3 Standard 2.5″ RFG MP Polymer Guides

- 1″ Bar, 3/4″ Pin, 48″ Long, 3 Long 2.5″ RFG MP Polymer Guides

- 1″ Bar, 7/8″ Pin, 48″ Long, 3 Standard 2.0″ RFG MP Polymer Guides

- 1″ Bar, 7/8″ Pin, 48″ Long, 3 Standard 2.5″ RFG MP Polymer Guides

- 1″ Bar, 7/8″ Pin, 48″ Long, 3 Long 2.5″ RFG MP Polymer Guides